About Global Lift Used Forklifts Chandler

Global Lift Chandler - Buying a forklift is not to be taken lightly. A forklift is a huge capital expense, and a complex machinery with a motor strong enough to execute heavy-lifting jobs. The price tag for a forklift varies from ten thousand dollars to thirty thousand dollars, comparable to the cost of a small truck. If buying a second-hand forklift, be certain to have it checked for possible mechanical problems.

There are two different types of forklift motor: internal combustion or electric. Forklifts with electric motors are usually more costly than those with internal combustion motors. The motor size must suit the type of work for which the forklift will be utilized. A forklift with a motor that is large costs more than a forklift with a motor that is smaller.

Gasoline or propane powered motors are usually stronger than electric motor and are capable of lifting heavier weight. The downside is that gas motors tend to develop issues more often compared to electric motors. Depending on the price of gas or propane, gas powered forklifts can be more expensive to operate compared to electric powered forklifts.

Several reliable manufacturers of forklifts are Mitsubishi Caterpillar, Crown Equipment Corp., NACCO Industries and Toyota Industries. Prior to deciding, research the various manufacturers and the availability of parts. Reviews, testimonials and prices can be found on line.

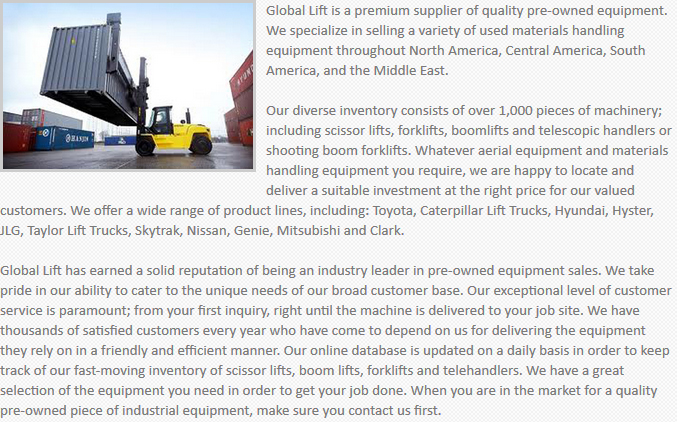

A forklift are a kind of machinery that enables an operator to easily and efficiently lift and transport things that are bulky and heavy. Forklifts are also called industrial-powered trucks. They are an important tool for moving merchandise and cargo through the logistical supply chain. Forklifts are either diesel- or gas-powered or electrically-powered. Gas-powered kinds run on diesel, liquid propane gas or gasoline. Training in forklift operation and safety, such as proper fueling methods, is very important for all operators of forklifts.

There are various types of forklifts meant for different applications and settings. Types of forklifts include narrow aisle, side loader, reach trucks and sit-down units. Your selection of a forklift depends on the specific tasks which would be performed\done.

In the United States alone approximately 100 people are killed in forklift-related accidents each year. Many more individuals receive serious injuries in forklift accidents. Correct safety training is necessary to reduce the possibility of accident.

Forklifts are powered either by diesel, battery, propane or gasoline. Each and every different kind is suitable to a different workplace setting.

Forklifts come with metal forks that are utilized to carry heavy materials. Possible attachments comprise buckets, clamps and hoists.

In warehouse environments, forklifts have to maneuver in very narrow aisles and have a tight turning radius. There are specific types of forklift made for this kind of environment. Narrow aisle forklifts allow a warehouse or distribution center to provide more space to commodities.

On the back of the forklift is a counterbalance, that allows the forklift to lift very heavy objects. The counterbalance provides balance so that the machinery would not tip over while lifting and transporting heavy loads. Forklifts are rated based on their load capacity. A small forklift that could lift one thousand eight hundred kilograms weighs around 4000 kilograms, that is equivalent to two full-size pickup trucks. The largest forklifts could have up to 36,000 kilograms of lifting capacity.

In utilizing a forklift, there are many safety issues. Like for example, travel in reverse when driving down a ramp. You must also haul a load in reverse if the cargo interferes with vision and is bulky. Operators must know how to mount the lift safely using the "three-point stance." This includes putting the right hand on the back of the seat, while holding the upright of the safety cage utilizing the left hand and placing the left foot on the step. On no account must you jump out of a forklift even in a tip over. It is actually safer to remain inside the confines of the lift. Any fall or slip on a forklift can result in serious injuries.

Forklifts are considered indispensable tools in many businesses as they can be used to efficiently and quickly unload and load things and supplies safely and with little physical exertion. Pedestrian safety is a primary consideration when operating in public spaces. Operators should always give pedestrians the right-of-way. A forklift must never be driven on a highway or on uneven grounds. The driver must have a seat belt fastened all the time while driving.

Forklifts would always be necessary pieces of machine for businesses since forklifts are an essential tool in any culture that makes and consumes mass-produced products. OSHA supervises compliance standards for businesses which utilize forklifts and provides certification and licensing protocols. The Forklift Rodeo is an entertainment event for operators and other workers which involves an obstacle course and other interesting spectacles.

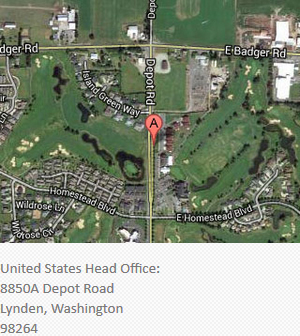

Contact Info

Questions or Comments